Inspection & Testing

As one of the leading companies in lifting equipment inspection, PT Rigspek Perkasa is committed to providing continuous excellent services and solutions. By having more than 15 years of extensive experience in inspection and testing across industries such as Oil & Gas and Marine, we can support your company to maintain your valuable asset that leads to a healthy and safe environment. As a full member of LEEA (Lifting Equipment Engineer Association), we have established various inspection procedures to comply with LOLER and PUWER. In addition, our qualified Inspectors and Engineers will be very supportive of giving the following services that also comply with national regulations, and client specifications:

- Lifting equipment inspection and testing

- Lifting Appliances

Offshore Crane, Mobile Crane, Hoist, Winches, MEWP, etc. - Lifting Gear

Shackle, Wire Rope Sling, Chain Sling, Webbing Sling, Round Sling, Hook, turnbuckle, Link, Plate Clamp, Eyebolt, etc. - Wire Rope Inspection

Crane, Towing, Mooring, Spare wire rope, etc - Container Examination

Offshore Container, ISO Container, Tank Container, Portable Offshore Unit, Gas Rack, Bulk Container, Waste Skip, etc. - Pad Eye Testing

Up to 50 MT Capacity - Horizontal Pull Testing

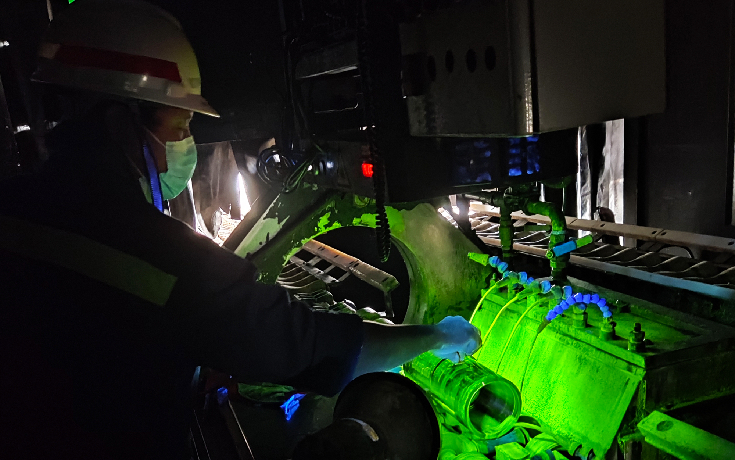

- Non-Destructive Testing

- Magnetic Particle Inspection

- Dye Penetrant Testing

- Ultrasonic Testing

- Eddy Current Testing

- Electromagnetic Testing for wire rope

As LEEA Certified Inspector will conduct technical services, lifting equipment inspection and testing will be concerned with a high standard of safety. Our calibrated tools and equipment can help us give the best inspection and testing practices. The following scope is our expert in inspection and testing:

The inspection report and certificate will be created by an online reporting system and database ‘OLIER’ that had developed by PT Rigspek Perkasa to support our customers continuously in monitoring documents. This system can be accessed by clients or customers to help them maintain and control their document reports, equipment status, and history.

OLIER is a integrated digital platform which allow inspectors to create, share and keep inspection reports include the origin certificate of clients or end users within all-in-one cloud-based system. The system is fully flexible and work across all devices and operation system platforms. This method of working means clients can work from anywhere, as long as they have access to the internet.

PT Rigspek Perkasa has the biggest Horizontal Test Bed Machine in Indonesia with Max. 1000 MT Capacity. Its capability is for wire rope load testing and destructive testing complete with Control Room for load monitoring and generating the report.

PT Rigspek Perkasa has the biggest Horizontal Test Bed Machine in Indonesia with Max. 1000 MT Capacity. Its capability is for wire rope load testing and destructive testing complete with Control Room for load monitoring and generating the report.

Feature:

Max. Cap. 1000 MT

Load Monitoring

Automatic Reporting System

Certified by ABS

Dimension:

Inside length: 40m

Inside width: 1.4m

Depth: 760mm

NDT (Non-Destructive Testing) is a common method to find various defects in materials that may occur while manufacturing processes or are caused by fatigue in services. NDT is the process of inspecting and testing materials or components for discontinuities without destroying the parts or system. By knowing the defects at the beginning, we can minimize the risk of equipment failure in the future. We can provide the following methods to keep your assets fit for purpose: